Cart

0

0

No document

0,00 €

Total

Document successfully added to your shopping cart

Quantity

Total

There are 0 items in your cart.

There is 1 item in your cart.

Total documents

Total shipping

To be determined

Total

Search & filter

Search for a publication

Search & filter

Erosion performance with abrasive flow rate for abrasive waterjet rock cutting

wtc2015_full_oh

T. Oh / G. Joo / E. Park / G. Cho

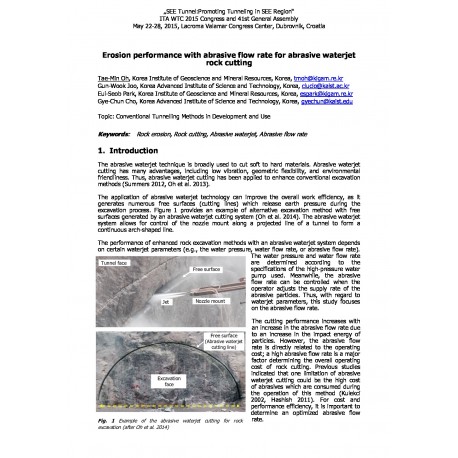

The abrasive waterjet technique is broadly used to cut soft to hard materials. Abrasive waterjet cutting has many advantages, including low vibration, geometric flexibility, and environmental friendliness. Thus, abrasive waterjet cutting has been applied to enhance conventional excavation methods (Summers 2012, Oh et al. 2013). The application of abrasive waterjet technology can improve the overall work efficiency, as it generates numerous free surfaces (cutting lines) which release earth pressure during the excavation process. Figure 1 provides an example of alternative excavation method with free surfaces generated by an abrasive waterjet cutting system (Oh et al. 2014). The abrasive waterjet system allows for control of the nozzle mount along a projected line of a tunnel to form a continuous arch-shaped line.